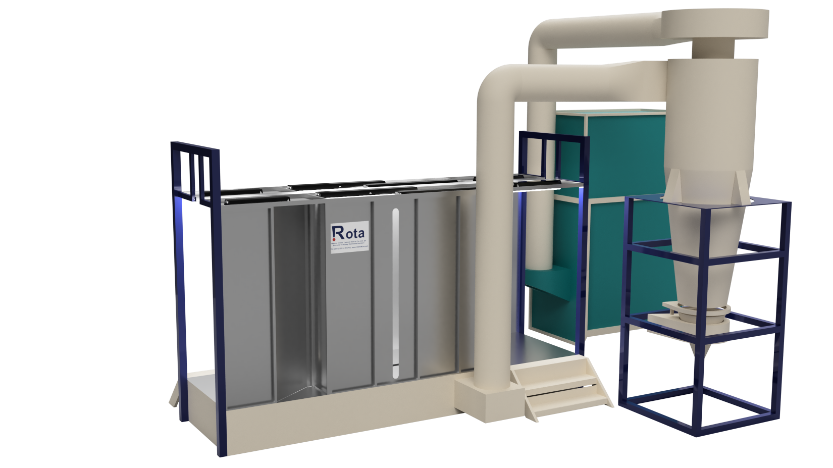

Our powder paint booths are manufactured as standard or custom design according to the customer’s needs. For the cabin selection, the dimensions of the parts and the targeted capacity are the determining elements. Our booths are made of stainless steel or galvanized sheet and fully assembled with bolts to easy disassembling.

Recycling is done with the cyclones in our powder coating booths with cyclone. It is preferred because it allows easy and fast color change. The powder particles which are not used passes through the cyclone unit before the filter unit. While the particles go down through cyclones with centrifugal effect, the particle that cannot be reused is sent to the filter unit and filtered there. The parts which are suitable for recycling are recycled to the system for reuse.

Multi and mono type cyclone units are used in our booths. Both types offer efficiency with recycling systems, practicality with easy color changing.

In filter cabins, it is necessary to change the filter group for color change. However, in cyclone cabins it is sufficient to clean the inside of the cabin and cyclone unit with compressed air only. Because of this, cyclone booths allow customers economical and very fast color change option in the painting process.

For our customers who want to add the paint powder that cannot hold on the part and pour into the base of the booth automatically, we also produce the booths with a Floor-Sweeping option.